Ultrasonic Testing

Main Content

Ultrasounds are the cyclic sound pressure above 20 kHz. Ultrasonic testing has been used as a common non-destructive evaluation (NDE) method for many decades and is also one of the most widely accepted NDE methods today. The frequency range normally applied during ultrasonic inspection ranges from 50 kHz - 50 MHz depending upon the applications and type of materials being inspected. Although ultrasound behaves in a similar manner to audible sound waves, it has a relatively shorter wavelength which means it can be reflected off very small surfaces such as discontinuities embedded inside materials. It is this property of ultrasound that makes it useful for NDE of materials.

Ultrasounds are the cyclic sound pressure above 20 kHz. Ultrasonic testing has been used as a common non-destructive evaluation (NDE) method for many decades and is also one of the most widely accepted NDE methods today. The frequency range normally applied during ultrasonic inspection ranges from 50 kHz - 50 MHz depending upon the applications and type of materials being inspected. Although ultrasound behaves in a similar manner to audible sound waves, it has a relatively shorter wavelength which means it can be reflected off very small surfaces such as discontinuities embedded inside materials. It is this property of ultrasound that makes it useful for NDE of materials.

The general idea of Ultrasonic NDE is based on the emission of an acoustic wave and recording of the signal after passing through the material being tested. If there is any difference in signal and time, it could signify a defect. Information obtained from ultrasonic waves include:

- Acoustic intensity and frequency.

- Time of flight measurements (allows detection of flaws).

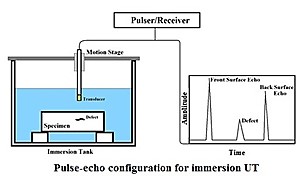

Ultrasonic testing can be performed in various configurations depending upon the application. Some of the common methods include pulse-echo, through-transmission, shear wave, pseudo-pulse echo, plate wave methods.

IMEL research mainly focuses on the application of longitudinal ultrasonic wave approach in pulse-echo and through-transmission modes.