Immersion Ultrasonic Testing

Main Content

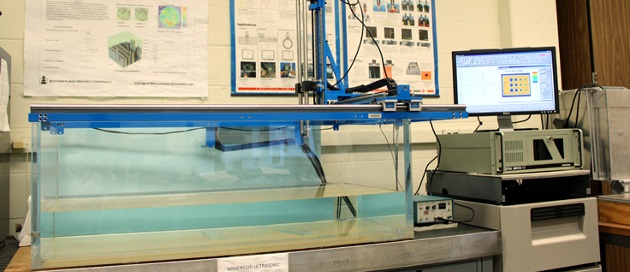

This ultrasonic NDE technique is used for flaw detection/evaluation, dimensional measurements, material characterization, and more for various friction materials. This method is based on using a liquid (water) as an ultrasonic couplant, in which the material and the transducer face are immersed in the tank, and the transducer is not in contact with the material. This system is multi-purpose ultrasonic testing equipment, featuring a large immersion tank and a computer controlled precision three axis motion for scanning. The experimental approach includes shear wave, pulse-echo, and through transmission methods.

Capabilities:

- Shear wave, pulse-echo, and through transmission measurements.

- Data collected through C-ScanTM software.

- Panametrics 5072PR as a pulser / receiver.

- Scan bridge and tank (40 in x 22 in x 16 in).

- Full motion control: motorized X-, Y- and Z- axes.

- 1, 5, 10, 15, and 25 MkHz transducers.

- Accurate A-scan, B-scan and C-scan.

Applications:

- Raw materials, casting, and forgings.

- Metals, composites, ceramics, and polymers.

- Carbon/Carbon composites.

- Carbon/Epoxy composites.

- Graphite-epoxy sandwich panels.

- Automotive clutch facings.

- Automobile brake pads.

- Asphalt concrete

- Weldments, adhesive bonds, pipe.