Automated Defect Recognition

Main Content

Our vision with Automated Defect Recognition (ADR) research is to contribute to the development of a formalized theory to embed intelligence at the sensor level for non-destructive evaluation (NDE), so as to improve the reliability of the processed NDE data and make an inspection job an unbiased, efficient, and effective process. The overall goal is to assist NDE inspectors in performing reliable and efficient testing.

An intelligent system (IS) is composed of a knowledge base, an inference engine, a working memory, a user interface, and an explanation based subsystem. IS can think and act rationally like humans to provide reasoned judgments to decision makers as a basis for action. The concept of an IS approach is not new. IS has been implemented as the decision-aid tool in various applications for many decades. In recent years, IS has gained more acceptance in aerospace, military, and many civil infrastructure applications to solve important problems, obtain consistent and reasonable results, and predict the reason for failure.

Most of the NDE engineers today often want to answer two basic questions when they are trying to classify damages induced in composites. First, where is the damage located? Second, what is the type, size, and extent of damage? Usually, existing NDE techniques are utilized to answer the first question based on the assumption that the NDE engineers have already discovered the damaged mechanism. If the type of damage can also be answered by NDE techniques, the robustness of any particular NDE system shall have a broader scope in future. In addition, conducting and interpreting NDE test results fully depends on the skill of the human operator. Also, NDE data is very difficult to interpret because it requires the analysis of a continuous signal for each point in the material under consideration. This is tedious and may lead to misinterpretation of the data results if not performed correctly. An automated process is therefore required to manage a large amount of signal data sets and extract important information from it. Due to these reasons, today, there is a greater demand for automated data interpretation in NDE industry.

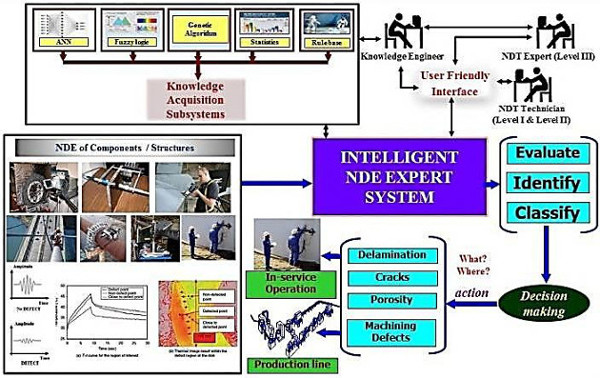

To accommodate these existing NDE needs, our current research focuses on the development of an intelligent nondestructive evaluation expert system (INES) for composite inspection. This novel approach integrates several intelligent methodologies (artificial neural networks, fuzzy logics, genetic algorithm, parametric and non-parametric statistical classifiers based on Bayesian, k-Nearest-Neighbor, Nearest-Mean, and rule based classifier) with expert knowledge to detect damaging events, characterize the nature, size/extent, and seriousness of the damage, and respond intelligently within the required timescale to mitigate the effects of the damage or its repair. In addition, this system will have a user friendly interface where a knowledgeable engineer, NDE experts, and NDE technicians can communicate and continuously update the system with new knowledge and databases. We believe, this developed INES will be a much faster, more efficient, and more effective process compared to traditional NDE systems. Furthermore, the trained system for one data set may be reused to classify other data sets with similar characteristics. Finally, this developed system can be implemented with a wide range of NDE methods and applications.

Intelligent NDE Expert System (INES)