Flash Heating IRT

Main Content

Flash Heating Infrared Thermography

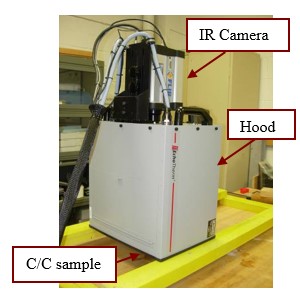

Flash Heating Thermography or Pulsed Thermography (PT) is one of the most common thermal simulation method widely used today in NDE field. In this approach, a short thermal pulse, typically lasting a few milliseconds, is applied into the material of interest during experimentation. The temperature of the material rapidly changes after the application of initial thermal pulse as the thermal front propagates by diffusion under the surface. A high-speed infrared camera is often employed to record the temperature of the material’s surface as the heat energy diffuses through the material. The video sequence is then processed to enhance the contrast of relatively “warm” (or “cold”) spots/areas on the surface that result from thermal reflections caused by material flaws.

Flash Heating Thermography or Pulsed Thermography (PT) is one of the most common thermal simulation method widely used today in NDE field. In this approach, a short thermal pulse, typically lasting a few milliseconds, is applied into the material of interest during experimentation. The temperature of the material rapidly changes after the application of initial thermal pulse as the thermal front propagates by diffusion under the surface. A high-speed infrared camera is often employed to record the temperature of the material’s surface as the heat energy diffuses through the material. The video sequence is then processed to enhance the contrast of relatively “warm” (or “cold”) spots/areas on the surface that result from thermal reflections caused by material flaws.

IMEL research using Flash IRT is also accompanied by finite element analysis (FEA) modeling in order to determine the theoretical transient thermal response of the materials that are subjected to flash heating.

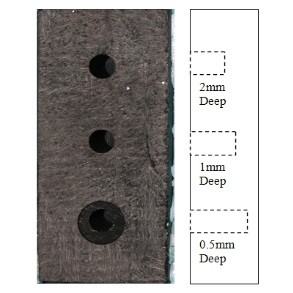

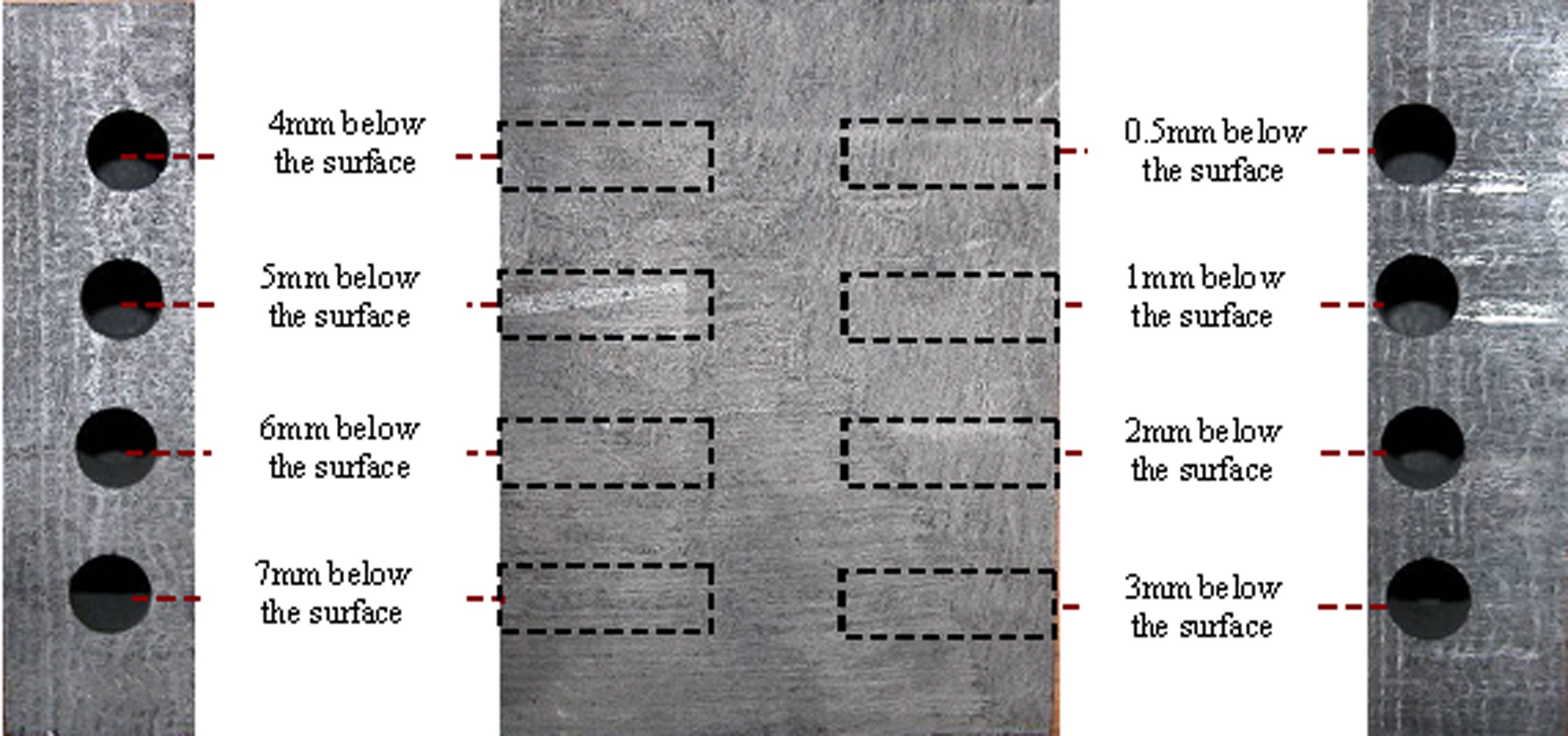

Defect Map for the blind hole Carbon/Carbon Composite Samples

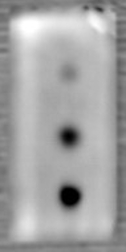

Flash IRT Results

Capability:

- Data measurement collected through MikroSpec R/T and Matlab

- 320x240 pixels focal plane at 60 Hz frequency frame rate

- Temperature Resolution: 0.06 °C at 30 °C, 60 Hz

- Minimum Resolution: 0.025inch x 0.025 inch

- Nominal Shot Size: 8 inch x 6 inch

- Nominal Capture Duration: 5 to 15 sec. per shot

- Four halogen bulbs for Illumination Head (4000W or 2000W)

- Temperature Range -40 °C to 2000 °C

- Focusing Range of 300 mm to infinity

- Real-time image recording (1664 images at 60 Hz)

Application:

- Metals, composites, ceramics, and polymers

- Carbon/Carbon composites

- Carbon/Epoxy composites

- Graphite-epoxy sandwich panels

- Honeycomb sandwich panels

- Automotive clutch facings

- Automotive brake pads

- Asphalt concrete