Infrared Thermography

Main Content

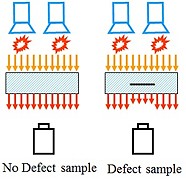

An infrared thermography (IRT) method measures or maps the surface temperatures as heat flows to, from, and/or through an object. Then, interior defects are easily identified by the drop in temperature values or represented as “hot spots” in thermal images. IRT can be divided into two approaches: the passive and the active/transient approach. The passive approach tests materials and structures which are naturally at different (often higher) temperature than ambient while in the case of the active approach, an external stimulus is necessary to induce relevant thermal contrasts. Active thermography is generally classified into four methods, which are Pulsed Thermography (PT), Step Heating (SH), Lock-in Thermography (LT) and Vibro-Thermography (VT). The table below shows the classification of active infrared thermography approach based on the application of excitation source.

|

Excitation Waveform |

Category |

Excitation Source |

Source Duration |

|---|---|---|---|

|

PULSE |

Flash Heating |

Xenon Flash Lamps |

Milliseconds |

|

PULSE |

Transient Heating |

Halogen Lamps |

Few Seconds to Minutes |

|

LOCK-IN |

Repetitive Heating |

Halogen Lamps Ultrasonic Heating Mechanical Heating |

Sinusoidal or Rectangular 0.01 Hz ~ 20 Hz Seconds to Hours |

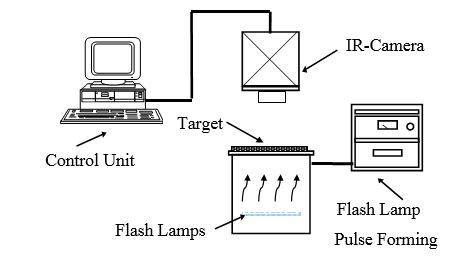

IMEL research mainly focuses on the application of the transient infrared thermography approach. A typical transient thermography system is shown below.

In this approach, a short thermal pulse lasting from a few milliseconds, for high-conductivity material such as metal and carbon-carbon materials, to a few seconds, for low-conductivity specimens such as graphite-epoxy laminates, is often utilized. During this process, the temperature of the material changes rapidly after the initial thermal pulse because the thermal front propagates by diffusion under the surface.