Step Heating IRT

Main Content

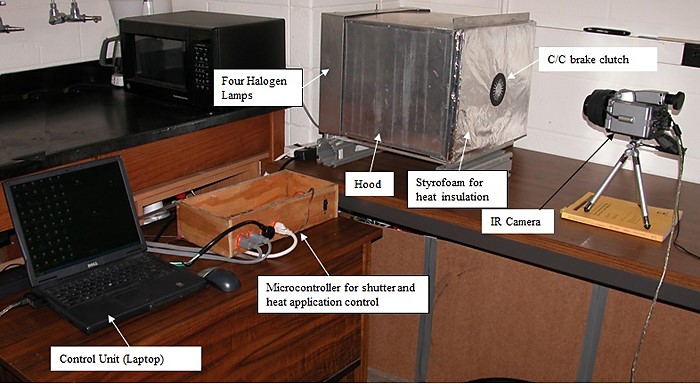

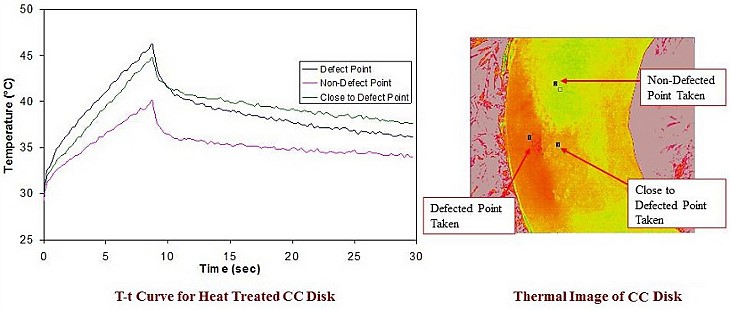

Step-Heating IRT approach uses an instantaneous constant heat flux while the increase in surface temperature is monitored during testing. Experiments are conducted by using four halogen linear tubes as the heat source and an infrared camera to record video sequence in order to determine baseline experimental data to compare with the FEA models.

Capability:

- Data measurement collected through MikroSpec R/T and Matlab

- 320x240 pixels focal plane at 60 Hz frequency frame rate

- Temperature Resolution: 0.06 °C at 30 °C, 60 Hz

- Minimum Resolution: 0.025inch x 0.025 inch

- Nominal Shot Size: 8 inch x 6 inch

- Nominal Capture Duration: 5 to 15 sec. per shot

- Four halogen bulbs for Illumination Head (4000W or 2000W)

- Temperature Range -40 °C to 2000 °C

- Focusing Range of 300 mm to infinity

- Real-time image recording (1664 images at 60 Hz)

Application:

- Metals, composites, ceramics, and polymers

- Carbon/Carbon composites

- Carbon/Epoxy composites

- Graphite-epoxy sandwich panels

- Honeycomb sandwich panels

- Automotive clutch facings

- Automotive brake pads

- Asphalt concrete

- Coating-substrate bond integrity

- Evaluation of coating thickness including multilayered coatings